Biosolids & Wastewater Applications

Wastewater treatment facilities across the country are facing mounting challenges in managing biosolids. Traditional disposal methods—particularly land application—are under increasing scrutiny due to concerns over PFAS contamination, nutrient runoff, and long-term environmental impacts. Regulatory agencies are tightening restrictions, and public resistance to biosolids land spreading is growing. At the same time, landfill and incineration options are diminishing as capacity shrinks and disposal costs surge, leaving municipalities and utilities with fewer, more expensive pathways for biosolids management.

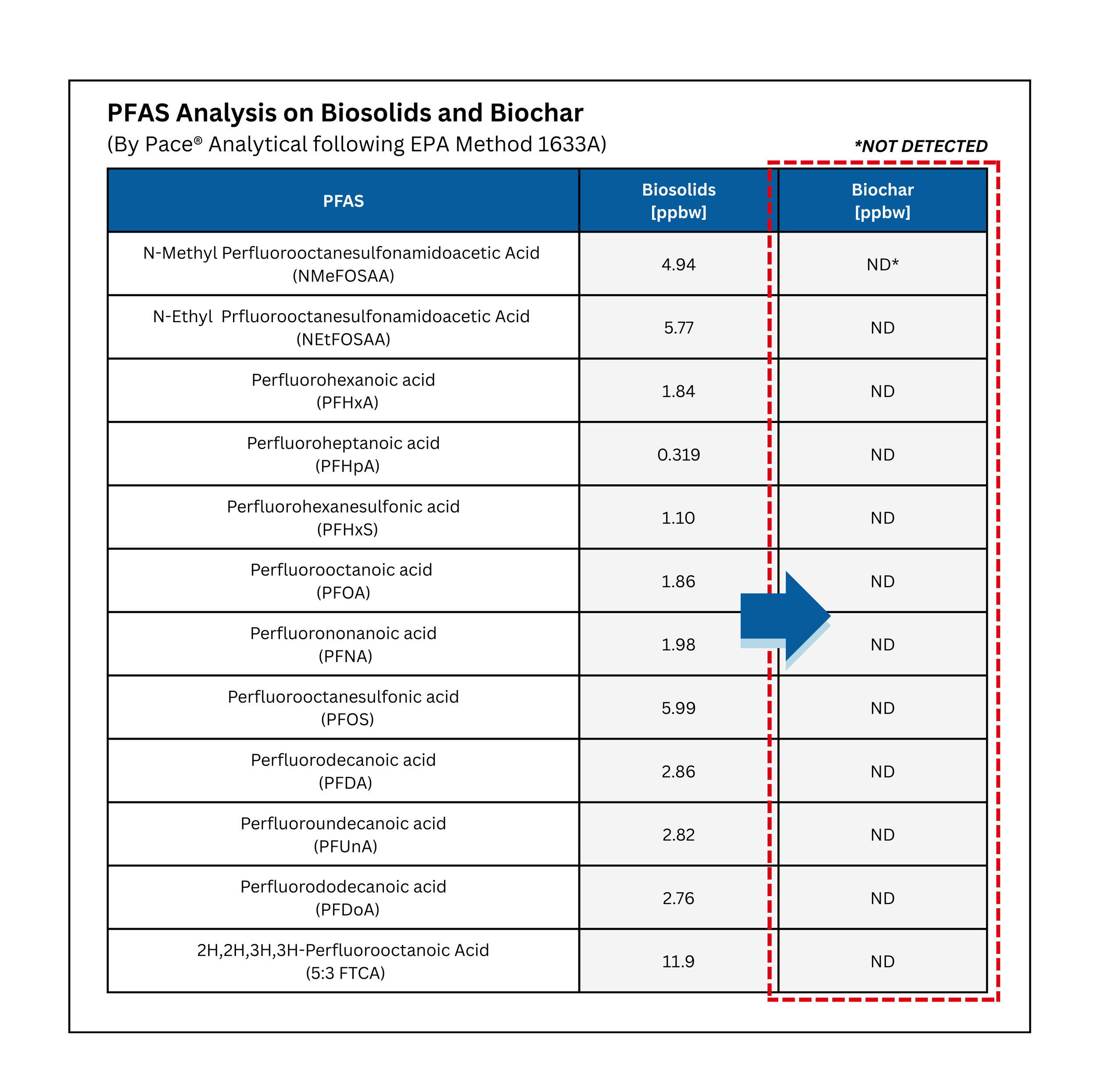

Pace Analytical Testing Confirms Trashology Pur-Gen System Produces PFAS-Free Biochar from Biosolids

Trashology’s Pur-Gen technology offers a sustainable, on-site alternative that eliminates the need for offsite biosolids disposal. The system dries and converts biosolids into a high-energy fuel, which is then cleanly gasified to generate electricity and heat. This modular solution reduces disposal costs, minimizes regulatory exposure, and eliminates PFAS and pathogens through high-temperature processing—turning a costly waste stream into a renewable energy resource.

Designed for flexibility and scalability, the Pur-Gen system adapts seamlessly to facilities of all sizes—from smaller plants treating 1 million gallons per day to large-scale operations exceeding 50 MGD. With modular units processing 1 to 5 dry tons per day, expanding capacity is as simple as adding additional modules—no costly infrastructure overhaul required. Whether you’re managing municipal biosolids or tackling tough industrial waste from food processing, textiles, or pulp and paper, Pur-Gen delivers a clean, cost-effective, and on-site solution that transforms waste into renewable energy.

The Pur-Gen system is a compact, self-contained solution designed to make biosolids processing simple, sustainable, and scalable. Key features include:

Fully containerized design requiring just 640 to 1,000 square feet, ideal for 1 to 5 MGD facilities

Accepts dewater biosolids with a solids content around 20-25%.

Uses internal thermal energy to dry biosolids for gasification

Fully automated operation—no dedicated operator required

High-temperature process that effectively mineralizes PFAS chemicals

Produces nutrient-rich biochar for use as a compost additive providing carbon sequestration opportunities

No outside energy required! It is a self-powering system that generates excess electricity for on-site use